Establishing Controls - PPE: The Last Line of Defense

Here at GovGig, we have frequently discussed the importance of establishing controls on the projects in which we work in an effort to protect our workers. We are always seeking more effective and informative ways in which to better manage occupational risk.

Ensuring that our workplace is free from recognized hazards that have the potential to hurt, or kill is our overall goal. Unfortunately, complete hazard removal is not always feasible or possible. There will be times during the course of our work when even the strictest of controls will not completely eliminate all risks associated with our tasks. Where residual risk exists after controls have been implemented, Personal Protective Equipment (PPE) helps make the difference.

Personal Protective Equipment is designed to protect workers from injuries or illnesses stemming from exposure to chemical, biological, physical, mechanical, electrical, or any other hazards to which a worker may be exposed in the workplace.

While an essential element to workplace controls, please remember that PPE should never be your first and only control against hazards. It is still, however, a vital part of the way in which we protect ourselves from harm. As you develop controls via the Activity Hazard Analysis process, we should first identify ways in which to control exposure to risk before turning to PPE.

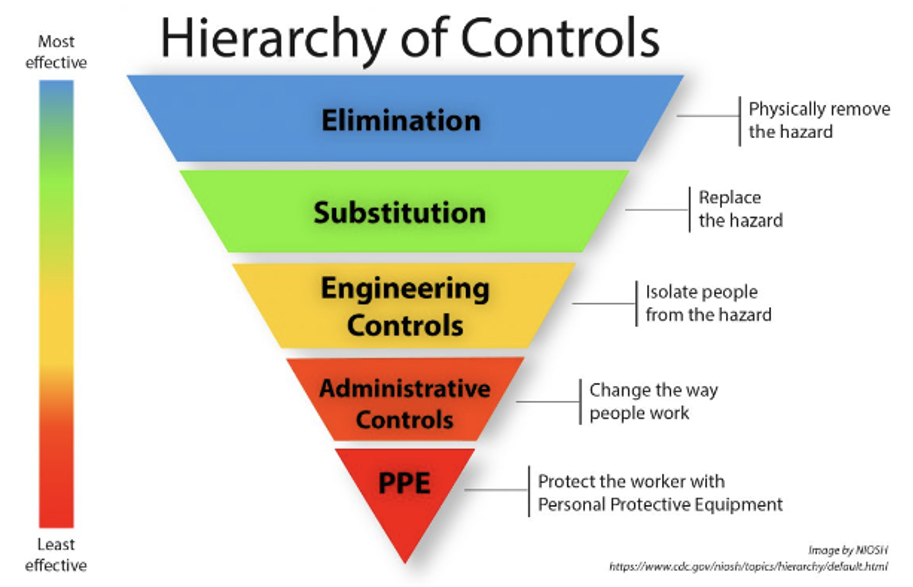

The National Institute for Occupational Safety and Health (NIOSH), a division of the CDC has established guidelines relating to the control of occupational exposures. They have established five levels of action to reduce or remove hazards. The higher the hierarchy of control, the more effective that control will be in protecting workers from harm. Consider the following graphic to help illustrate this point:

Levels of controls are broken down into the following categories in order of general effectiveness:

1. Elimination of the hazard completely removes the hazard at the source. This could include changing the work process to stop using a toxic chemical, heavy object, or sharp tool. Elimination is the preferred method as completely removing the hazard eliminates worker exposure.

2. Substitution refers to utilizing a safer alternative to the source of the hazard. Effective substitutes, while typically not completely removing hazard exposure, can greatly reduce the harmful effects of the task to which workers are exposed to.

3. Engineering Controls can refer to various methods by which the work tasks, or workspace has been modified to protect workers. This could include areas such as the implementation of ventilation systems to remove respiratory exposures to harmful vapors, and the installation of a protective barrier such as a machine guard or guardrail system among many more. NIOSH has established an Engineering Controls Database which provides examples of established engineering controls that you might consider.

4. Administrative Controls aim to establish work practices “that reduce the duration, frequency, or intensity of exposure to hazards.” This type of control could include established procedures for safe work practices, employee training, posting safety-related signage to warn workers of hazards, and implementation of job rotation to minimize exposure, among others.

5. As we have established, PPE, while the least preferred control, is still vital for ensuring that workers are protected from harm. PPE used will depend upon the work process being performed and the environment in which workers are performing work. Be sure to assess your individual workplace for PPE needs via a PPE Hazard Assessment prior to beginning work.

In conclusion, employers should not rely strictly on PPE alone to reduce employee exposure to harm until all other options have been exhausted. PPE can be an effective solution in conjunction with other controls to minimize worker exposure only when used correctly and consistently. As you work to identify hazards for the tasks in which you perform, first work to control or eliminate hazards in the workplace through hazard elimination, substitution, engineering, and administrative controls before relying strictly on the use of PPE. As we plan our work with a controls-based focus on protecting our workers, we can meet our goal of successful project completion with zero incidents.

Please reach out to us here at GovGig if you would like assistance with this process.

Cory J. Grimmer